HHL series One machine refrigeration dryer purification equipment

Save space:

Help users save space when there is not enough installation space.

Cut coat:

Dryer and filter integrated design, saving time and manual installation and maintenance costs.

Energy saving:

Aluminum alloy three in one heat exchanger design reduces the process loss of cooling capacity to the minimum, improves the recovery and utilization of cooling capacity, and reduces the total input power of the model by 15-30% under the same treatment capacity.

Efficient:

The integrated heat exchanger is equipped with guide fins to make the compressed air evenly heat exchange inside, and the built-in air-water separation device is equipped with stainless steel filter screen to make the water separation more thorough.

Intelligence:

Multi channel temperature and pressure monitoring, real-time display of dew point temperature, automatic record of accumulated running time, self diagnosis function to display corresponding alarm code, automatic protection of equipment.

Environmental protection:

In response to the international Montreal agreement, R134a, R410A and R407C environmental friendly refrigerants are all used for this series of aircraft, and the degree of damage to the atmosphere is zero to meet the needs of the international market.

Stable:

The standard constant pressure expansion valve is equipped with intelligent temperature control laboratory to test that when the air inlet temperature reaches 65"C and the ambient temperature reaches 42C, it still operates stably and has double antifreeze protection of temperature and pressure, and automatically stops the output of compressor during long-term low-load operation. The refrigeration capacity reserved by aluminum plate exchange is used to provide heat exchange and energy saving, while prolonging the service life of the equipment.

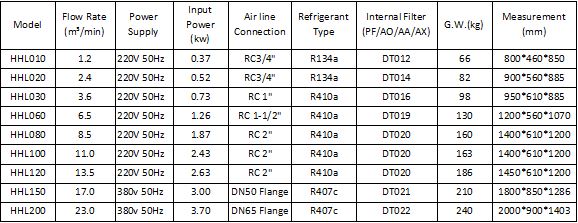

Product model parameter table

Rated condition& Technical requirements

Rated ambient temperature: 38℃ ,maximum42℃

Rated inlet temperature of compressed air: 38℃, maximum 65℃

Rated compressed air pressure: 0.7MPa, maximum 1.6Mpa

ressure dew point under rated working condition: 2℃- 10℃(atmospheric dew point: -23℃--17℃)

Installation environment: no sun, no rain, good ventilation, installed on horizontal hard foundation, no obvious dust and flying floes

Air Process:

Thecompressed air flows into the Pre-Cooler via inlet to perform preliminarycooling, then flows into cooling system evaporator to be further cooled viacooling system. The cooled compressed air is sent to the condensate separator, and the condensate liquid is discharged out of the machine viaauto-discharger. The cooled and dry compressed air will return to the heatexchanger for temperature regaining, then leave the frozen dryer via airoutlet.

Coolant Flow:

Thecoolant that flows through the Coolant Compressor is in a state of hightemperature and high pressure liquid, such liquid coolant is cooled down intomedium temperature and high pressure coolant via water cooled or air cooled condenser.The impurities are filtered via Drying Filter, and the coolant turns intolow temperature and low pressure air-liquid mixed state via capillary effect. It finally enters into the evaporator to implement heat exchangewith the hot compressed air to finish the cooling process, then returns to theCoolant Compressor and work cyclically.

For more information about the specification,welcome to contact us!

Phone:0755-28686438

E-mail:yuka@szyuka.cn